Taking advantage of waste products such as wood chips, waste sludge, tree bark ... the group of scientists from the Institute of Chemical Engineering (Hanoi University of Technology) is conducting research on technology to produce single-cell proteins to used in the production of animal feed. This is considered as a green research direction, contributing to environmental protection and sustainable development.

Research on technology to produce single-cell proteins from paper industry by-products

Actively source materials

The project "Research on technology to produce single-cell proteins from paper by-products and application in the production of animal feed", belongs to the Project on Biotechnology Development and Application in the field of processing industry to in 2020, assigned by the Ministry of Industry and Trade to the Institute of Chemical Engineering to deploy.

Associate Professor, Dr. Le Quang Dien - Project leader - said that single-cell protein is considered as a stable protein source of the future, to meet human needs, as well as as a source of food for families cattle. In particular, single-cell proteins are produced on agricultural, industrial, and forestry preparations, including waste from the paper industry. Therefore, this is considered as a research direction contributing to environmental sustainability.

According to Assoc.Prof. Dr. Le Quang Dien, currently paper materials are mainly acacia (accounting for 70% of the materials used). The country's output of wood chips of paper materials reaches 7-8 million tons / year, used for domestic pulp production and export.

However, during chip processing (chopping), 2% of the chips are formed, which can be obtained during the screening and washing of the chips. Thus, the amount of wood scrap in the form of wood chips can reach thousands of tons, concentrated in pulp and chip processing enterprises.

In terms of properties, chips and chips have the same chemical composition as wood (polysacccharide content> 70%), but due to their small size, they are not suitable as raw materials for pulp production. Furthermore, chips are lignocellulose materials that are less biodegradable and easy to collect and store. "Therefore, it is appropriate to take advantage of this type of scrap to convert into sugar and use it for the production of microbial proteins as animal feed" - Assoc.Prof. Dr. Le Quang Dien said.

Meet domestic demand

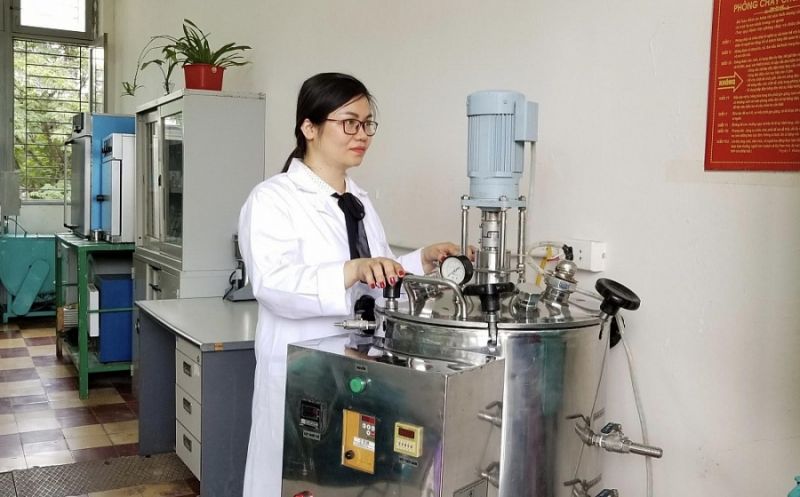

The goal of the project is to select strains of yeast growing on the transformation from acacia wood scrap; building technology processes and models of semi-industrial equipment for the production of single-cell proteins from colloidal wood scraps, and applied as feed for livestock and poultry ...

The technological process of producing single-cell protein from colloidal wood scrap, is built on the basis of modern technology to produce protein from lignocellulose material in the world, on a semi-industrial scale, can be converted into large-scale production. Similar technology is not available in the country.

Assoc.Prof. Dr. Le Quang Dien said that the demand for single-cell protein for animal feed is very large. Therefore, the success of the topic will open a new direction for the paper industry, possibly transferring this technology to businesses of pulp processing, pulp production, and final processing. Domestic livestock feed as well as cooperating with livestock and poultry farms as a partner in supplying food with guaranteed and stable nutritional value.

Through the implementation of the topic, the facilities applying research results will solve the problem of manufacturing waste with appropriate technology, creating value-added products, meeting domestic demand. about animal feed.

Source: congthuong.vn